Building a Travel Quad.

Damage | Posted on

Damage | Posted on  Sunday, December 8, 2013 at 02:00PM

Sunday, December 8, 2013 at 02:00PM

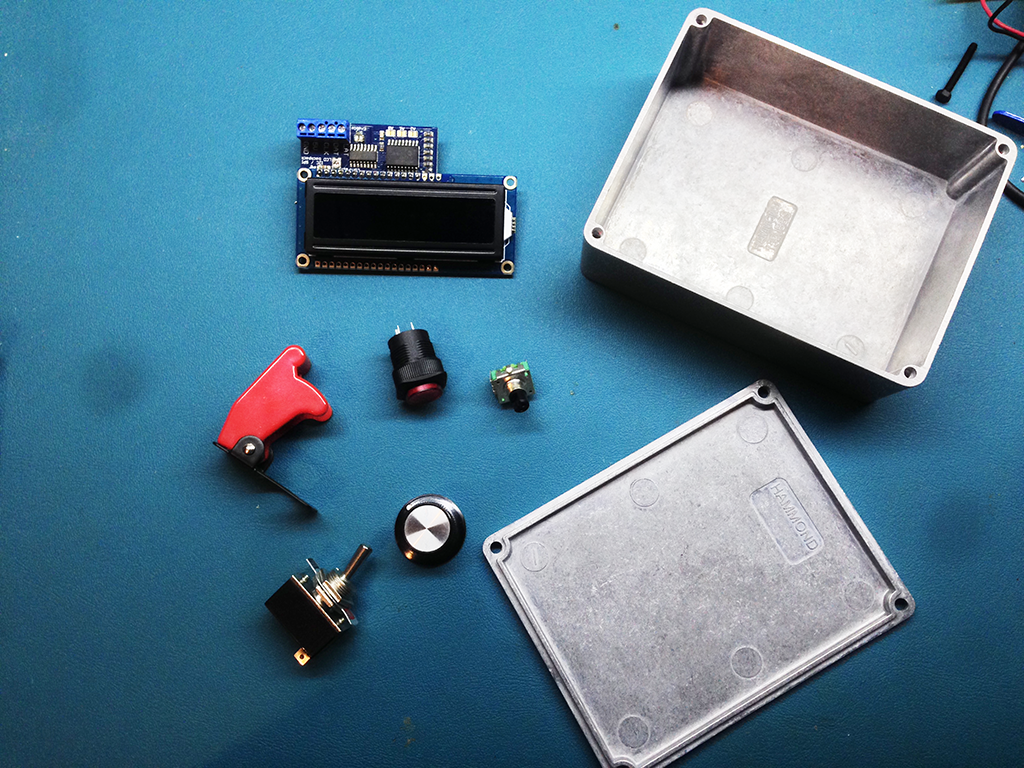

I am on the quest for the Holy Grail, or at least my version of it. I am looking to visit some friends in Hawaii sometime next year and I am looking for the perfect drone to take with me to capture video of some of the more scenic areas there. My requirements are as follows...

- Must be as small as possible for travel

- Must get decent battery life (10mins is the goal)

- Must be able to carry a Go-Pro camera

- Must have smooth video

- Must be stable in the air and fly well

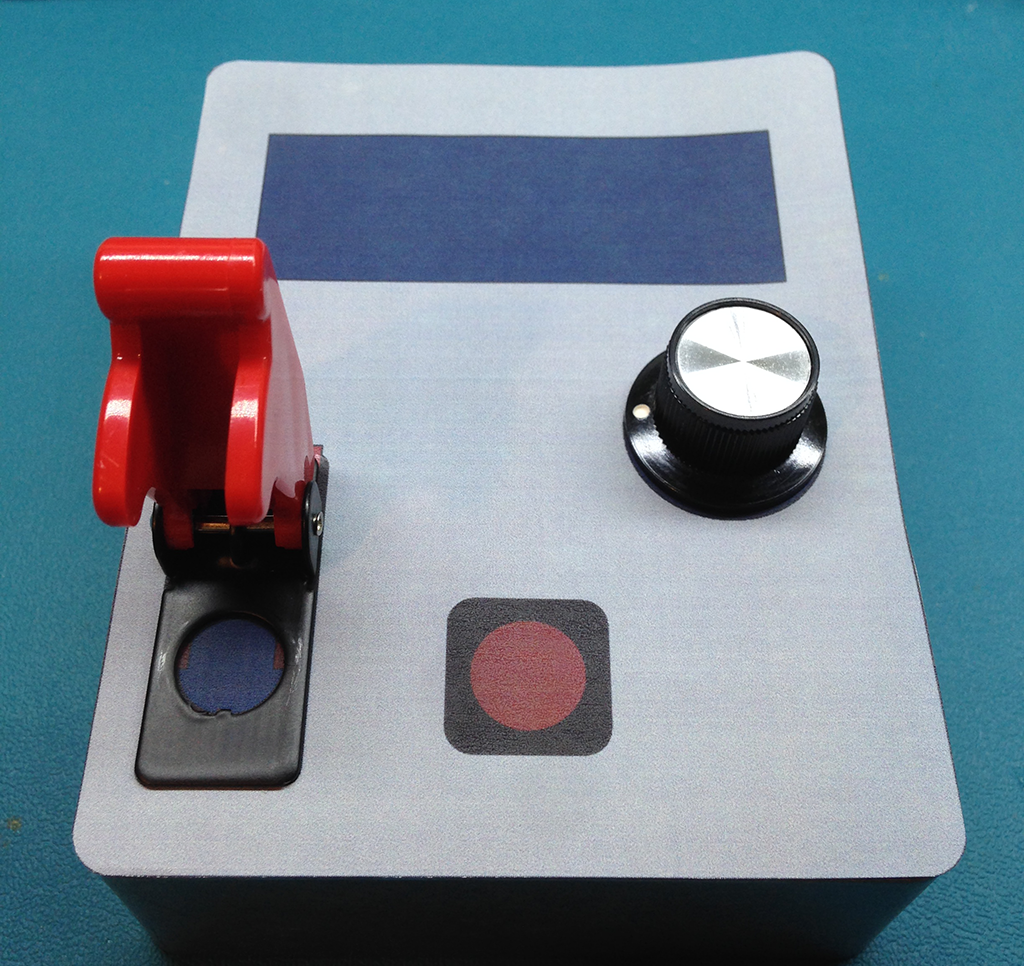

This quad which I have named the "Aloha Quad" aims to fit that bill. It is based on the Flite-Test rotorbones knuckles which I have outfitted with my own custom modifications.

To reduce vibration, I will use the necessary evil (Weight) that I must carry to my advantage. There is no getting around it, I must carry a battery, camera, flight electronics, etc, but where I choose to place them might work to help eliminate vibration.

Taking a cue from the QAV 500, it seems that having a vibrationally "dirty" section where your motors, and props are isolated from the "clean" section where the electronics and camera reside might offer the best solution.

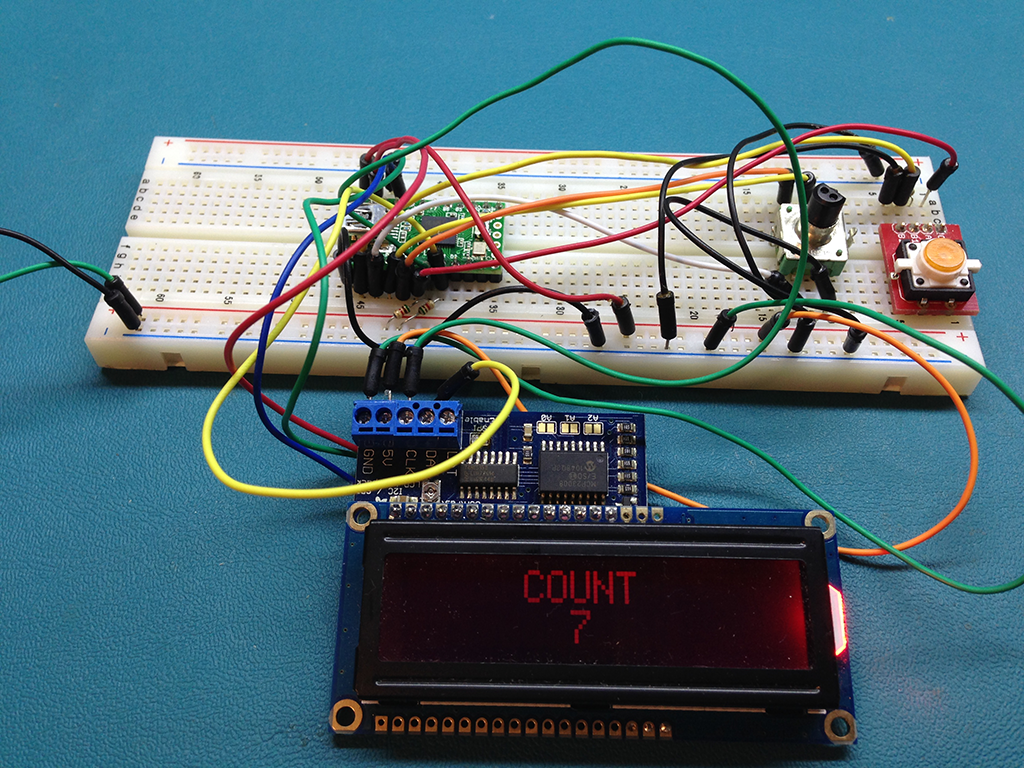

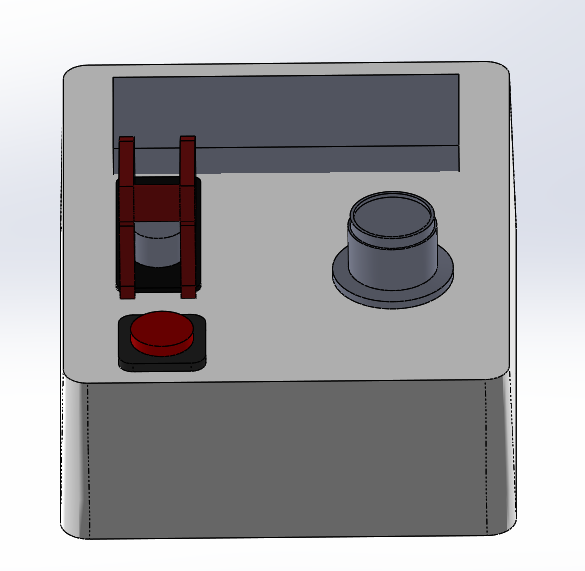

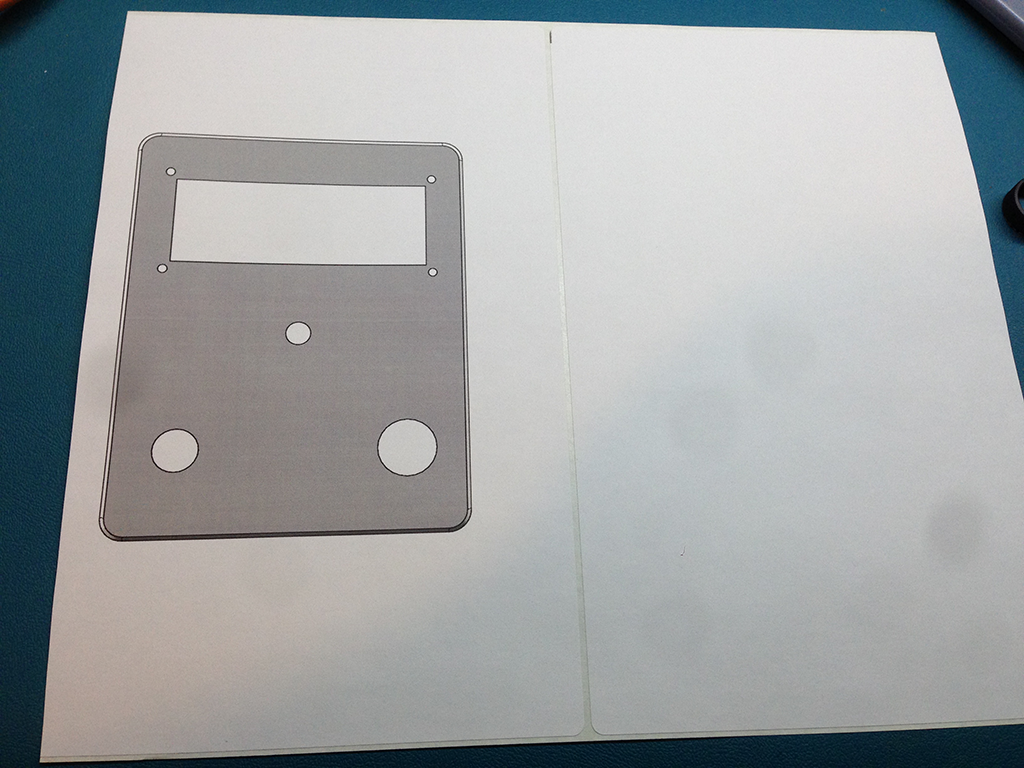

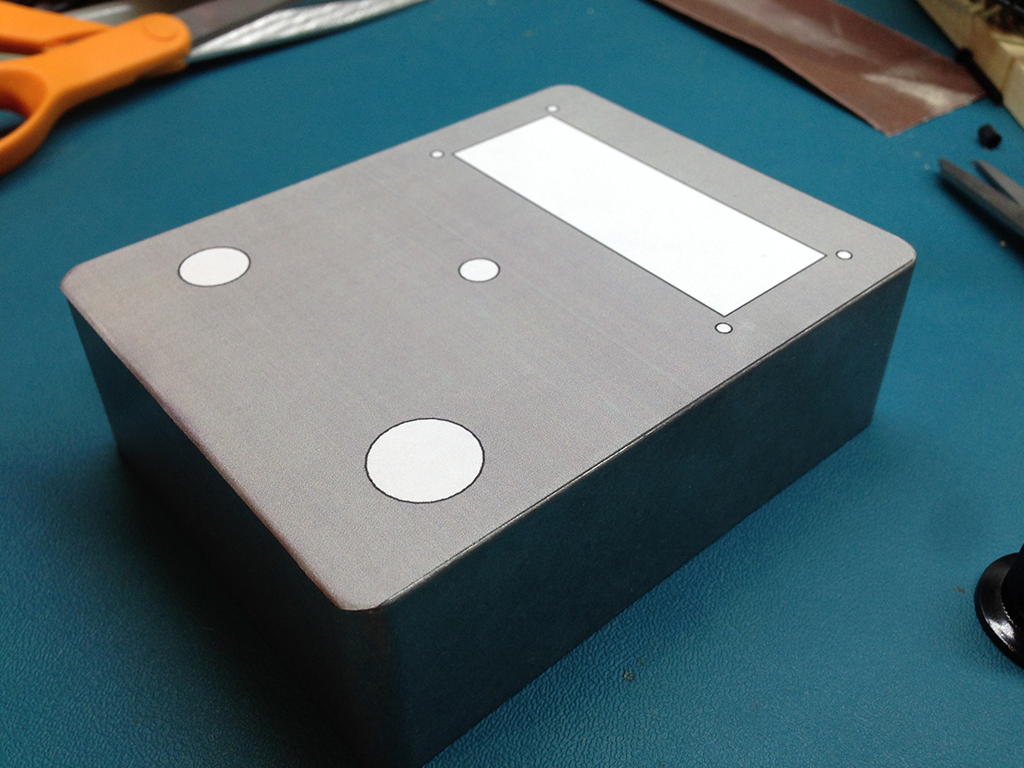

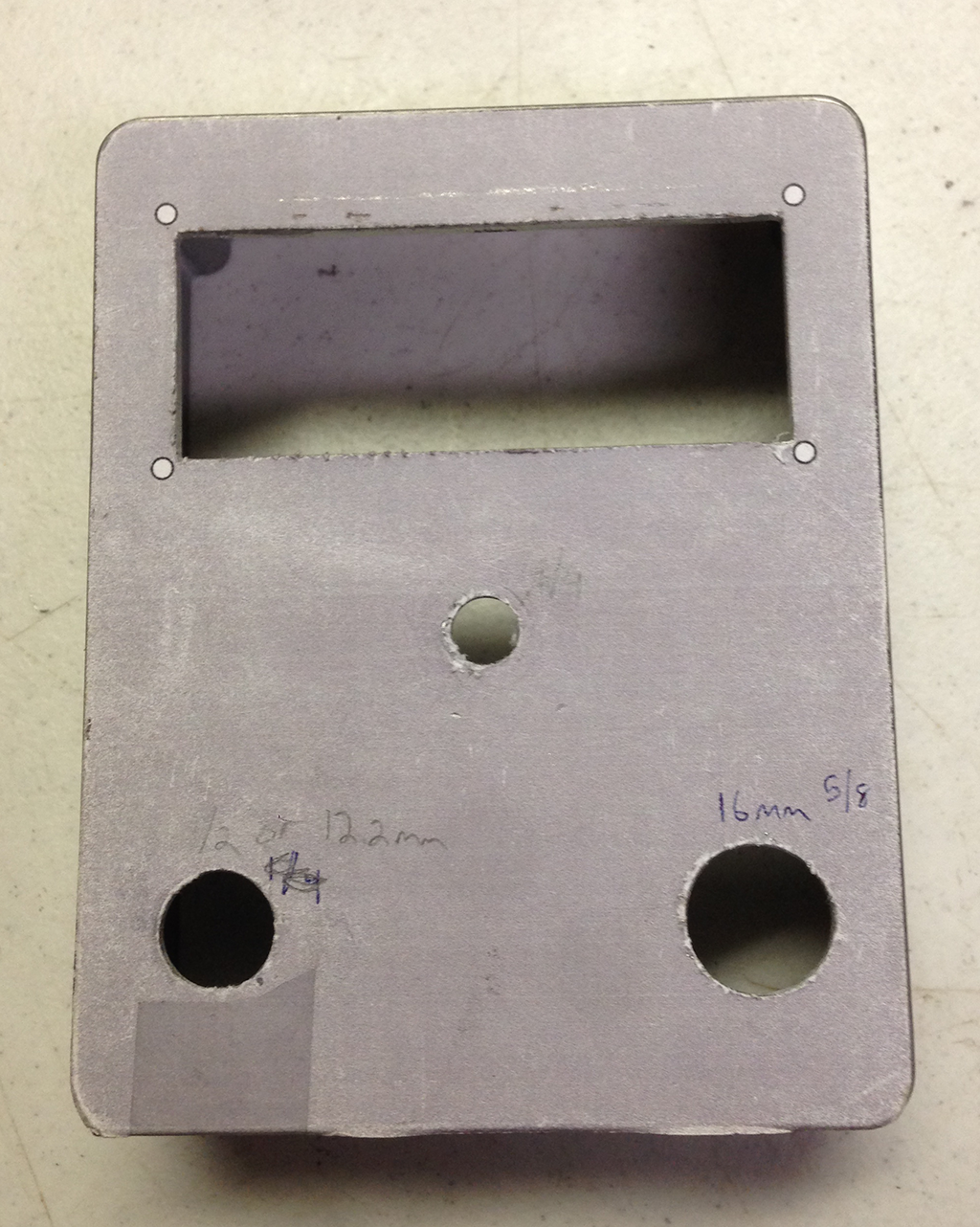

Here I present the first version RevA

OK, so what's going on here? First I created a plate out of acrylic which I cut on the laser cutter down at Baltimore Hackerspace. The idea is the plate will carry the weight of everything I can mount on to it which will provide inertial resistance.

This plate will be isolated from the rest of the frame using vibration dampeners. I have a variety of different hardness dampeners to experiment with to determine which offers the best solution...

This plate will be isolated from the rest of the frame using vibration dampeners. I have a variety of different hardness dampeners to experiment with to determine which offers the best solution...

Ultimately this design failed. As it turns out, the CG was too high which caused the drone to become quite unstable in flight. See the following video for an example.

Ultimately this design failed. As it turns out, the CG was too high which caused the drone to become quite unstable in flight. See the following video for an example.

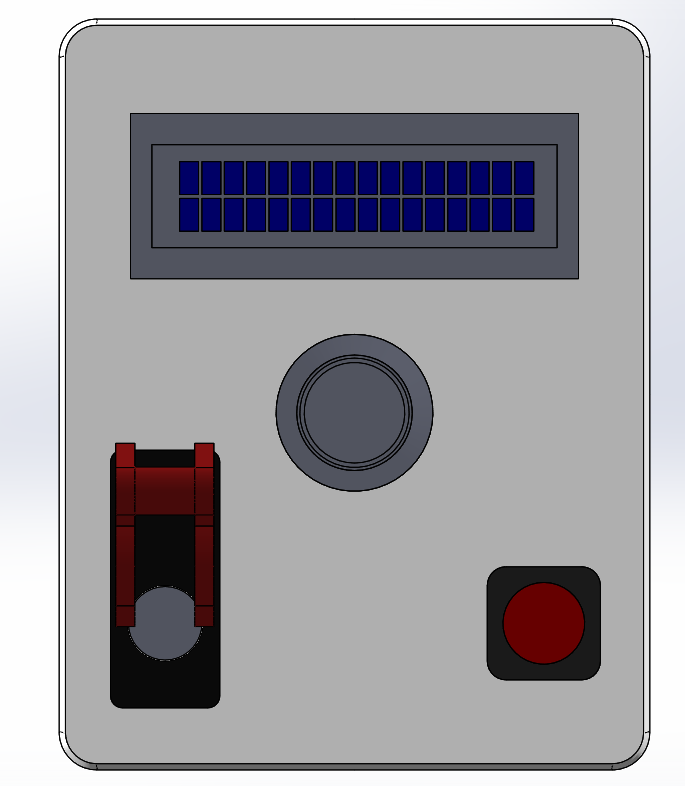

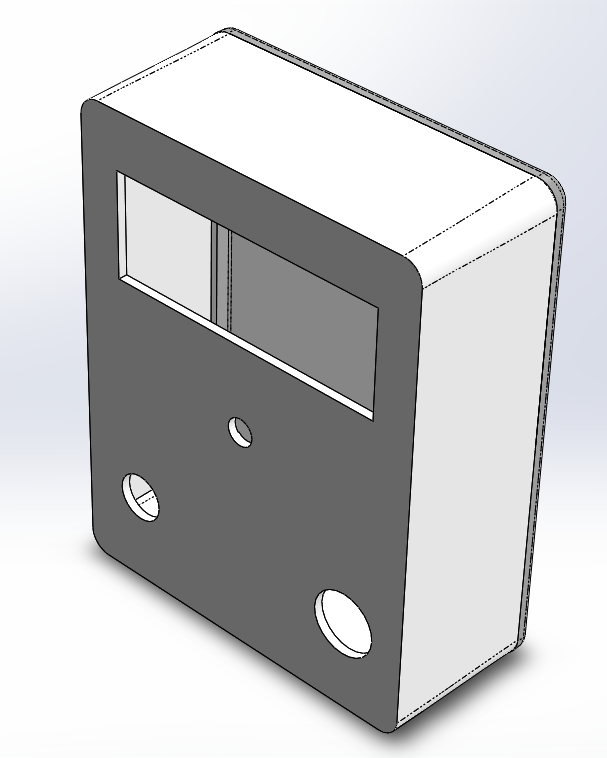

My idea to correct this is to relocate the plate to the bottom. I am still putting the finishing touches on the design, once I have it finished, I will update my progress on this page. Here is a render of what I have so far....